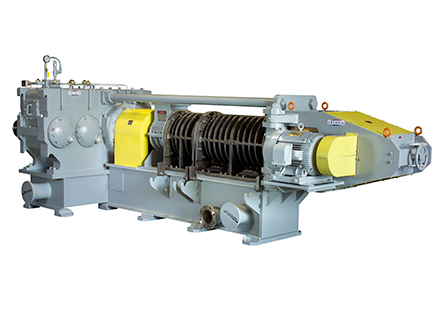

French Dewatering Screw Press models are designed for all types of synthetic rubber and other polymers. They accept a free-drained feed material in a 40-60% water content range and dewater the material by expression to a discharge moisture in the 6-12% range.

Custom Designed Mechanical Drying and Dewatering Screw Press Systems

Our commercial size dewatering equipment is designed to meet the unique process requirements of the customer. Many models are available; and the particular model best suited for the job will depend on capacity and type of material and amount of water to be removed:

- The capacity determines the diameter (7", 10.25", 14", 16", and 18" diameters are available). Capacity ranges of 500 kg/hr to 12 metric tons/hr. Gearbox and machine designs range from 150 hp to 1,500 hp.

- The type of material and amount of water to be removed determines the length-to-diameter ratio. Our machines can range from 3:1 to 6:1.

Download our dewatering equipment brochures to learn more about the our synthetic rubber dewatering screw press designs and capabilities.

PRODUCT DESIGN BY TYPE

Product Literature Downloads

Special features of French Dewatering Screw Presses

- French Cone Mechanism – This provides an adjustability through a 360 degree uniform annular opening. This controls the pressure exerted on the material and the amount of water removed.

- Proprietary shaft arrangement design and barrel construction for efficient water removal and low solids loss.

- Strong, heavy-duty mechanical design to overcome any upset condition and provide a long life with low maintenance.

- Shaft support on both ends results in very little rubbing and wear and the ability to use standard materials of constructions instead of more costly wear resistant materials.

- We offer high-quality spare parts for our dewatering screw press models – both our current models and our first presses manufactured in the 1950’s and later, like the G4-88.

French Dewatering Screw Press Models:

G2-44

G2-66

H2-66

N-66

N-88

Do you have a material that is very difficult to dewater? Usually we can handle it with our dewatering screw press; but when necessary, we have a two-stage model that has two cone mechanisms, one mounted mid-press and one at the discharge. This machine will give the ultimate in control and consistency, a necessity in a mechanical drying finishing line.

Request a Polymer Quote

We want to help you attain optimum process results that meet and exceed industry standards. Partnering with us, we will provide you a custom solution based on your type of natural or synthetic rubber and thermoplastic production. Contact us now!

PRODUCT DESIGN BY TYPE

Product Literature Downloads

Service & Support

The French Oil Mill Machinery Company provides solutions that Fit Your Exact Needs — Aftermarket Parts, Maintenance, Rebuilds, Retrofits

Request a Quote

Tailored Solutions for Your Manufacturing Needs: Achieve Optimal Process Results with Our Customized Equipment and Specialized Solutions.